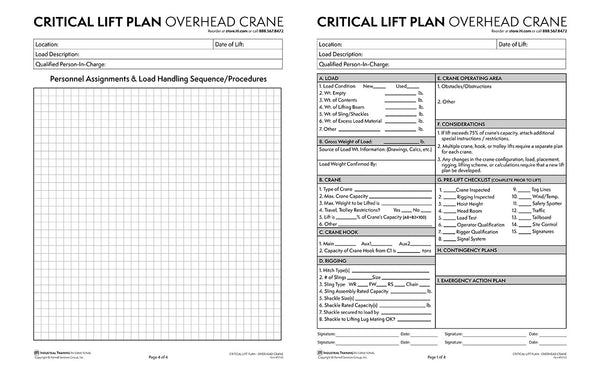

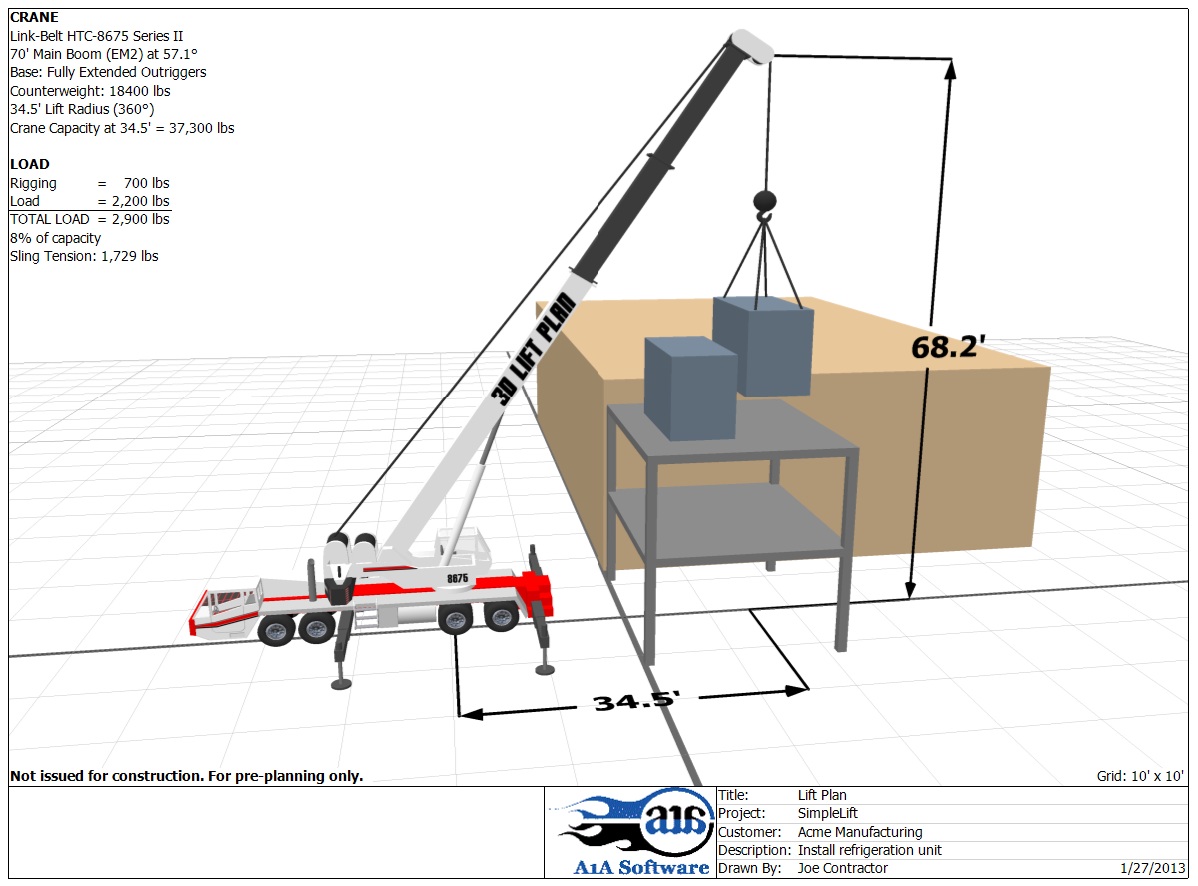

Without proper planning, the critical lift can turn deadly. Environmental conditions, including the ground conditions.Įach of these elements ensures a safe lift in critical conditions.Percent of the crane’s rated weight capacity.The position and configuration of the crane or cranes involved.It must have the following information in it: Parts of a Critical Lift PlanĪn experienced supervisor will be able to complete a critical lift plan with ease. Because the potential of crane failure or catastrophic loss is much higher with a critical lift, critical lifts require a thorough lift plan. Occurs in unknown ground conditions or poor soil.Īny time that environmental conditions make the lift dangerous or any time a crane operator believes the lift is critical, the lift can qualify as critical.Īll crane lifts require pre-lift planning.Involves technically difficult rigging arrangements.

Occur in a blind spot, out of the view of the operator.More than weight capacity qualifies a lift as a critical lift.

Maximum capacity refers to 70% to 90% of a crane’s capacity. When a plan goes right, the cranes move smoothly, with operators and supervisors working in a beautiful rhythm.īefore the lift, though, much planning takes place.Īnytime a hoisted load nears a crane’s maximum capacity, the load qualifies as a critical load. Planning a Critical LiftĬranes and hoists working in tandem are like poetry in motion. Keep reading to learn about the engineering specifics involved in a critical lift. Without proper planning and execution, an operation can quickly turn into an OSHA statistic.

The critical crane lifts require planning, experienced supervision, and precise execution. A tandem lift is a tricky, dangerous operation.

0 kommentar(er)

0 kommentar(er)